Applications

CURVED SURFACES

Imagine being able to print on a curved surface like a bottle, a golf ball or an egg, without needing additional focus or pixel corrections! Our unique process enables us to print on curved surfaces with the same speed and accuracy as others can on flat surfaces only. This means that you can now mark or brand your products in new ways, without sacrificing your production line velocity.

NEW MARKETING OPPORTUNITIES

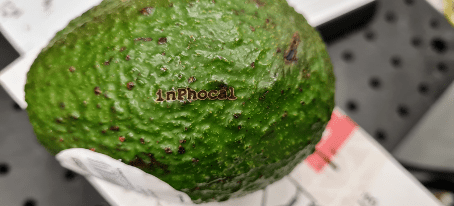

Branding is an essential element of any business, large or small. It’s what sets your company apart from the competition and helps customers remember your products or services. The wider reach of the printing area means you can include more branding elements, in areas that are hard to print on with conventional printers. For example, you can now brand fruits, vegetables or event eggs directly on their peel, without a need for plastic stickers, and most importantly – without compromising on the speed of your production line. This new way of inkless branding fits really well on the current market, which is continuously craving more sustainable packaging solutions. By taking advantage of the novel ink-less branding opportunities afforded by our patented laser technology, you can give your business a distinct edge in the marketplace.

Sustainability

inPhocal’s plug-in solution not only enables a much needed transition to inkless marking and coding, it also significantly reduces the energy consumption. InPhocal’s laser systems consume up to 50x less energy compared to the conventional inkjet technologies. Make your production line future-proof with inPhocal’s sustainable solutions.

INCREASED PRODUCTION

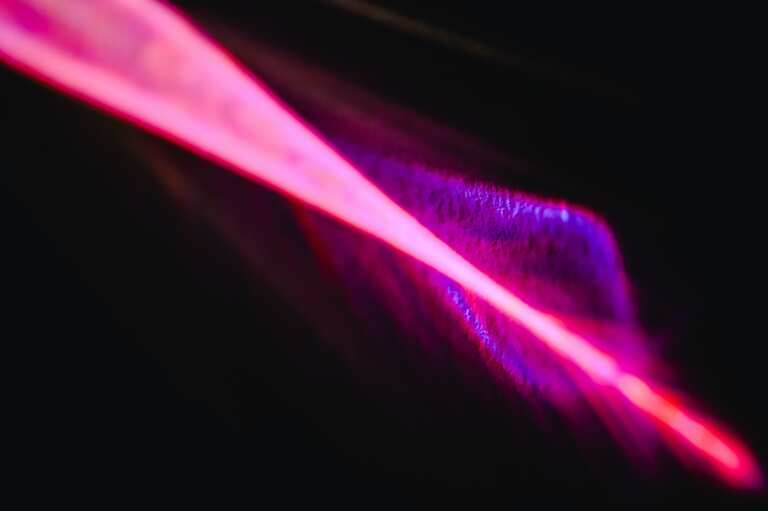

The inPhocal laser is a cutting-edge technology that can increase production while reducing downtime. Unlike traditional printing methods, the inPhocal laser uses a focused beam of light to cut through or print on a material. This makes it possible to produce intricate designs with clean, precise edges. In addition, the inPhocal laser is much faster than other printing methods, making it possible to increase production without sacrificing quality. And because there is no ink involved, there is no need for nozzle replacement or messy cleanups. As a result, the inPhocal laser is an ideal solution for businesses that need to increase production without incurring additional costs.

EASY INTEGRATION

Ease of integration is an important factor to consider when choosing a new production line component. The integration of inPhocal’s laser solution is straightforward and can be accomplished without alterations in most production lines. Book a demo at our lab and our technicians will show you how our laser systems work, and in what ways they can be integrated into your already existing production line – without unnecessary downtime or extra costs.